In today’s various engineering projects, there is such an unassuming yet crucial “invisible guardian”, and that is the geomembrane. Perhaps you are not unfamiliar with its name, but do you really understand its wonders? Today, let’s unveil the mysterious veil of it together and see how it demonstrates its capabilities in different fields.

I. Robust Body with Outstanding Properties

The Geomembrane is mainly made of high-molecular materials such as polyethylene (PE) and polyvinyl chloride (PVC), possessing astonishing physical properties.

It has extremely high tensile strength, just like dressing the earth in a tough armor, capable of withstanding enormous pressure and tensile forces. Whether in the anti-seepage reinforcement of dams or the leakage prevention treatment of landfills, it can firmly hold its position, effectively preventing the leakage and seepage of liquids and ensuring the safety and stability of the project.

Its chemical corrosion resistance is also remarkable. When facing various corrosive substances such as acid and alkali solutions and organic solvents, it shows no fear. With its stable chemical structure, it remains intact for a long time, providing a reliable protective barrier for groundwater resources and the soil environment.

Moreover, this product has excellent ultraviolet resistance.

After being exposed to sunlight for a long time, it can still maintain good performance without being easily aged or embrittled. This enables it to play a stable role in outdoor water conservancy projects, agricultural irrigation facilities, and other projects for a long time.

II. Wide Range of Applications, Everywhere

Water Conservancy Engineering Field

In the construction of water conservancy facilities such as reservoirs, dams, and canals, the geomembrane plays a vital role.

As an anti-seepage layer, it can effectively prevent water leakage, improving the water storage capacity and operation efficiency of water conservancy projects. For example, in the reinforcement project of a large reservoir, a high-quality geomembrane was used for the anti-seepage treatment of the dam body. After the completion of the construction, through long-term monitoring, the leakage volume of the reservoir was significantly reduced, not only ensuring the effective utilization of water resources but also providing a solid guarantee for the agricultural irrigation and domestic water use of the surrounding areas.

Environmental Protection Engineering Field

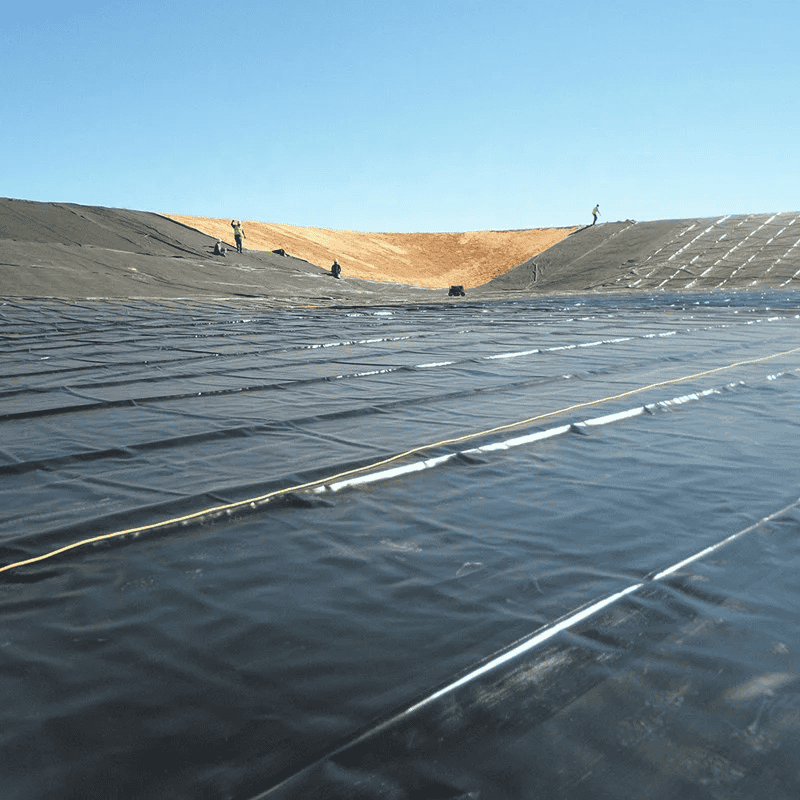

The landfill is another important application scenario for the geomembrane.

Here, the geomembrane is laid at the bottom and around the landfill pit, forming a tight anti-seepage layer to prevent the landfill leachate from polluting the groundwater and soil environment. At the same time, the geomembrane can also reduce the diffusion of harmful gases generated by the landfill to the surrounding environment, making an important contribution to environmental protection. According to statistics, the use of the geomembrane for anti-seepage treatment in landfills can reduce the pollution degree of the surrounding environment by more than 99%, greatly reducing the environmental pressure.

Agricultural Field

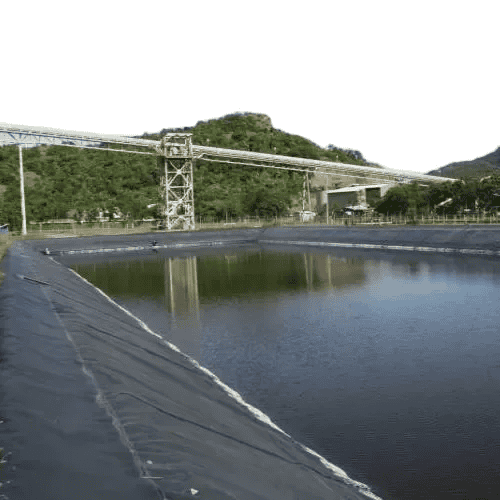

In agricultural production, the geomembrane also has a wide range of applications.

For example, in the construction of aquaculture ponds and irrigation storage ponds, the geomembrane can prevent pond water leakage, improve the utilization rate of water resources, and maintain the stability of water quality, providing a good living environment for aquatic organisms such as fish and shrimp. In addition, laying the geomembrane on the ground of agricultural greenhouses can also play roles such as heat preservation, moisture retention, and preventing the growth of weeds, helping to improve the yield and quality of crops.

III. Meticulous Manufacturing, Quality Assurance

The outstanding performance of the geomembrane is inseparable from advanced production processes and strict quality control.

Manufacturers strictly control the selection of raw materials to ensure the use of high-quality high-molecular materials, ensuring the quality of the geomembrane from the source. During the production process, advanced process technologies such as extrusion and calendering are used to precisely control parameters such as the thickness, strength, and porosity of the geomembrane, making its various performance indicators meet national standards and industry requirements.

At the same time, each batch of geomembrane must undergo strict quality inspection before leaving the factory.The inspection items include multiple aspects such as tensile strength, elongation at break, puncture resistance, anti-seepage performance, and chemical corrosion resistance. Only products that meet all indicators can enter the market. This strict control of quality enables users to feel more at ease and confident when using the geomembrane.

IV. Future Prospects, Unlimited Potential

With the continuous progress of science and technology and the development of society, the application prospects of the geomembrane will be even broader. In fields such as new urbanization construction, sponge city construction, and ecological restoration, the geomembrane will play a more important role. For example, in the construction of sponge cities, the geomembrane can be used for the anti-seepage treatment of the rainwater collection system, improving the collection and utilization efficiency of rainwater; in ecological restoration projects, the geomembrane can be used in projects such as mine revegetation and wetland protection to prevent soil erosion and promote the restoration and improvement of the ecological environment.

The geomembrane, the invisible guardian of the earth, with its outstanding performance, wide range of applications, and reliable quality, has made indispensable contributions to our lives and the development of society. It is believed that in the future, it will continue to exert its unique advantages, provide solid guarantees for more engineering projects, and create a better tomorrow!