Fiberglass Geogrid is a high-performance geosynthetic material widely used in civil engineering and construction. Here is an introduction to it:

Definition and Structure

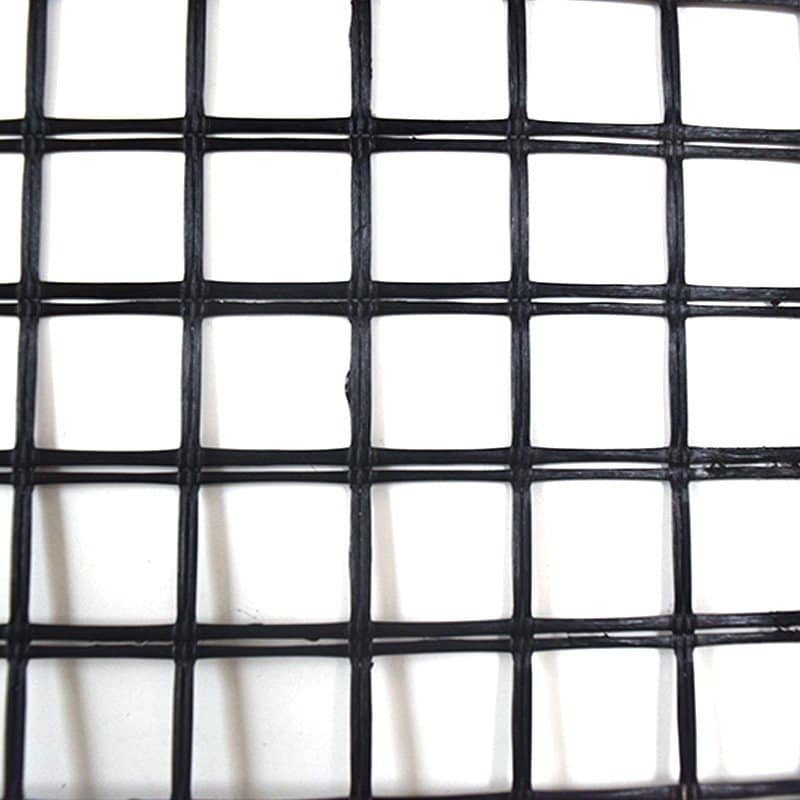

- Fiberglass Geogrid is a grid-like structure made of fiberglass yarns. The fiberglass yarns are typically high-strength and alkali-resistant, which are woven or knitted into a regular grid pattern. The grid structure is often coated with a special polymer material, such as polyvinyl chloride (PVC) or polyethylene (PE), to enhance its durability and resistance to environmental factors. This coating also improves the bonding performance between the geogrid and the surrounding soil or other materials.

Properties

- High Tensile Strength: Fiberglass Geogrid has excellent tensile strength, enabling it to withstand large pulling forces. It can effectively distribute and transfer loads in the soil, improving the overall stability of the ground structure.

- Low Elongation: It has low elongation under load, which means it maintains its shape and size with minimal deformation. This property is crucial in ensuring the long-term performance of the geogrid in engineering applications, as it can prevent excessive stretching and potential failure of the structure.

- Good Chemical Resistance: Similar to fiberglass in general, Fiberglass Geogrid is highly resistant to chemicals, acids, and alkalis. It can remain stable and functional in various soil and chemical environments, making it suitable for use in different geological conditions.

- Excellent Thermal Stability: It can withstand a wide range of temperatures without significant changes in its mechanical properties. This thermal stability allows it to be used in different climates and environments, ensuring its reliability and durability over time.

- Long Service Life: Due to its high-quality materials and excellent resistance to various factors, Fiberglass Geogrid has a long service life. It can maintain its performance and integrity for many years, reducing the need for frequent replacements and maintenance in engineering projects.

Applications

- Road Construction: In road engineering, Fiberglass Geogrid is widely used to improve the performance of asphalt pavements and subgrades. It can be placed between the asphalt layer and the subgrade to prevent the reflection of cracks, enhance the load-bearing capacity of the road, and prolong the service life of the pavement.

- Railway Engineering: It is used in railway subgrades to reinforce the soil and improve its stability. By restraining the lateral displacement of the soil particles, Fiberglass Geogrid helps to maintain the integrity of the railway subgrade, especially in areas with soft soil or high traffic loads.

- Slope Protection: For slope reinforcement and protection, Fiberglass Geogrid is an effective material. It can be installed on the slope surface to enhance the shear strength of the soil, prevent soil erosion and landslides, and improve the overall stability of the slope.

- Landfill Engineering: In landfill sites, Fiberglass Geogrid is used to reinforce the foundation and lining systems. It helps to distribute the load of the waste evenly, prevent the settlement and cracking of the landfill structure, and protect the underlying soil and groundwater from contamination.

- Retaining Wall Construction: When constructing retaining walls, Fiberglass Geogrid can be used as a reinforcement material. It increases the lateral resistance of the soil behind the wall, improving the stability of the retaining wall and reducing the risk of wall failure.

Installation Methods

- Manual Laying: In some small-scale projects or areas with limited space, manual laying is a common method. Workers unroll the Fiberglass Geogrid on the prepared ground surface, ensuring that it is laid flat and without wrinkles. The geogrid is then fixed in place using stakes or anchors at regular intervals.

- Mechanical Laying: For large-scale projects, mechanical laying is often preferred. Specialized laying machines are used to unroll and position the geogrid accurately and efficiently. These machines can handle large rolls of geogrid and ensure a more uniform and consistent installation.

- Overlapping and Jointing: When installing Fiberglass Geogrid, overlapping and jointing are necessary to ensure the continuity and integrity of the reinforcement. The overlapping width is usually specified according to the project requirements, and the joints can be bonded using adhesives or fastened with metal clips or staples.

Overall, Fiberglass Geogrid is an important and effective geosynthetic material that plays a significant role in enhancing the stability and performance of various geotechnical engineering projects, contributing to the safety and durability of infrastructure.