Polyester Geogrid is a kind of geosynthetic material with excellent performance, widely used in many engineering fields. The following is an introduction to it:

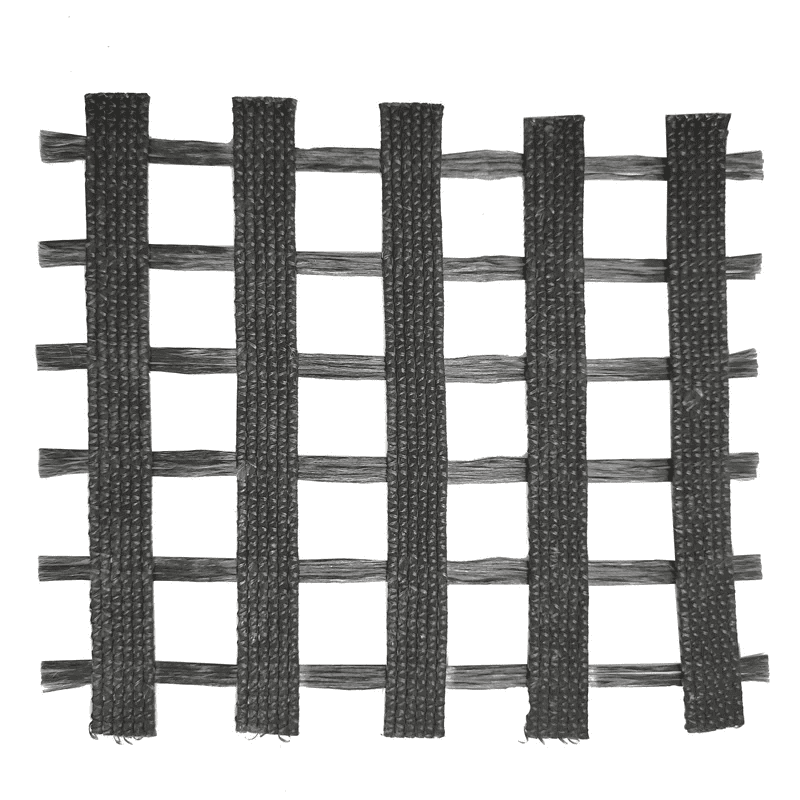

Definition and Structure

- Polyester Geogrid is a grid-shaped material mainly made of polyester fibers. It is usually manufactured through processes like extrusion and stretching. The polyester fibers are arranged in a regular grid pattern, with strong intersection points that enhance the overall structural stability. Some polyester geogrids may also have a surface treatment or coating to improve their performance in different environments, such as better resistance to moisture and UV radiation.

Properties

- High Tensile Strength: It possesses remarkable tensile strength, enabling it to endure substantial pulling forces. This property allows the geogrid to effectively bear and transfer loads in engineering applications, making it capable of enhancing the stability of the soil and other structures.

- Good Elongation at Break: Polyester Geogrid has appropriate elongation at break, which means it can undergo a certain degree of stretching without breaking easily. This property gives it good adaptability to ground deformation and settlement, helping to maintain the integrity of the reinforced structure in various geological conditions.

- Excellent Chemical Resistance: It shows strong resistance to a wide range of chemicals, including acids, alkalis, and salts. This makes Polyester Geogrid suitable for use in different soil environments and chemical conditions, ensuring its long-term stability and performance.

- Good Creep Resistance: Polyester Geogrid has excellent creep resistance, which means it can maintain its mechanical properties well under long-term load. This is crucial for engineering projects that require long-term stability, as it can prevent the geogrid from deforming or losing its reinforcement effect over time.

- UV Resistance: With proper treatment, Polyester Geogrid has good UV resistance. It can resist the degradation and aging effects of ultraviolet rays, which allows it to be used in outdoor environments for a long time without significant performance reduction.

Applications

- Road Engineering: In road construction, Polyester Geogrid is often laid between the subgrade and the asphalt layer. It can effectively prevent the reflection of cracks from the subgrade to the asphalt surface, enhance the load-bearing capacity of the road, and prolong the service life of the pavement.

- Railway Engineering: For railway subgrades, Polyester Geogrid is used to reinforce the soil and improve its stability. It helps to distribute the load of the train evenly, reduce the settlement of the subgrade, and ensure the safe operation of the railway, especially in areas with soft soil or high-speed railways.

- Embankment Engineering: When constructing embankments, Polyester Geogrid is used to enhance the stability of the embankment slope. It can increase the shear strength of the soil, prevent soil erosion and slope sliding, and improve the overall stability of the embankment, reducing the risk of collapse.

- Landscaping and Erosion Control: In landscaping projects, Polyester Geogrid is used for slope protection and erosion control. It can be covered with soil and vegetation to form a green slope, which not only beautifies the environment but also effectively prevents soil erosion and protects the ecological environment.

- Waste Disposal Engineering: In waste landfills, Polyester Geogrid is used to reinforce the foundation and lining systems. It helps to evenly distribute the weight of the waste, prevent the settlement and cracking of the landfill structure, and protect the surrounding soil and groundwater from pollution.

Installation Considerations

- Ground Preparation: Before installing Polyester Geogrid, the ground needs to be leveled and cleared of debris and sharp objects to ensure good contact between the geogrid and the ground and prevent damage to the geogrid.

- Laying Direction: The laying direction of the geogrid should be determined according to the stress direction of the project. Generally, it is laid along the direction of the maximum stress to give full play to its reinforcement effect.

- Overlapping and Fixing: When laying the geogrid, there should be an appropriate overlapping width between adjacent pieces, usually ranging from 10 to 30 cm, depending on the project requirements. The overlapping parts can be fixed with staples, nails, or special adhesives to ensure the connection reliability.

- Backfilling and Compaction: After the geogrid is laid, backfilling and compaction should be carried out in a timely manner. The backfill material should be evenly spread and compacted to ensure that the geogrid and the backfill material are closely combined and jointly bear the load.

Polyester Geogrid is a high-performance geosynthetic material with important application value in the construction and reinforcement of various geotechnical engineering projects, which provides strong technical support for improving the quality and safety of engineering projects.