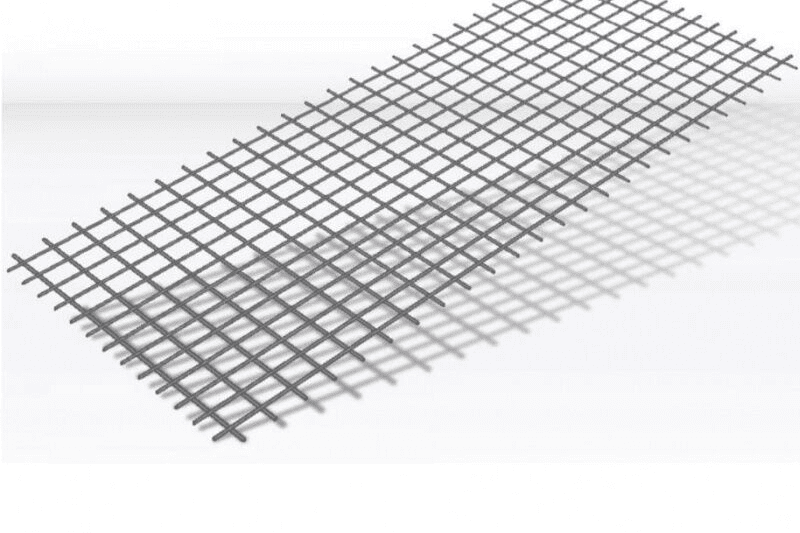

Fiberglass geogrid is a reinforced geotechnical product made of fiberglass material. It has very high strength and durability and is widely used in soil stability enhancement, road reinforcement, slope support and other geotechnical engineering. It has many advantages, such as improving the stability of soil structure, reducing settlement, and reducing maintenance costs, so it plays an important role in civil engineering and transportation infrastructure construction.

Fiberglass geogrid is made of high-quality glass fiber through a special process to form a high-strength mesh structure. Its main function is to transfer external loads to the soil and effectively enhance the shear strength of the soil. In this way, fiberglass geogrid can reduce soil deformation, inhibit settlement, and thus improve the stability of the structure.

Advantages of fiberglass geogrid

- High strength and high modulus: fiberglass geogrid has higher tensile strength than traditional geotextiles and other reinforcement materials, and can withstand greater loads. Its high modulus property enables it to effectively transfer stress and prevent settlement and cracks when reinforcing soil and pavement.

- Strong corrosion resistance: Fiberglass itself has excellent corrosion resistance and is not affected by moisture, acid and alkali environment, so it can maintain a long service life in various soil types and harsh environments.

- Easy construction: The installation of fiberglass geogrid does not require complicated construction technology. It only needs to be laid in the soil layer that needs to be reinforced, which can quickly improve the stability of the soil and save a lot of construction time and cost.

- Lightweight: fiberglass geogrid is light in weight, easy to carry and construct, and reduces transportation and labor costs.

- Environmental protection: fiberglass geogrid is made of harmless materials, will not pollute the environment, and has a long service life, which meets the environmental protection requirements of modern civil engineering.

Application fields of glass fiberglass geogrid

Glass fiber geogrid has a wide range of applications, especially in soil reinforcement and pavement engineering. Specific applications include:

- Pavement reinforcement; Glass fiber geogrid is often used to reinforce pavement in transportation infrastructure such as highways, railways and airport runways. It can improve the bearing capacity of the pavement, prevent cracks and rutting on the pavement, extend the service life of the pavement, and reduce the frequency and cost of maintenance.

- Slope support; Glass fiber geogrid plays an important role in slope support engineering, especially in slope reinforcement along highways and railways. It can effectively stabilize the soil, prevent slope sliding and collapse, and ensure the safety and durability of the project.

- Water conservancy engineering; Glass fiber geogrid is widely used in dam reinforcement, river slope protection and reservoir slope stabilization. Its high strength and durability can effectively prevent water erosion and soil loss.

Performance of glass fiberglass geogrid

- Tensile strength: Glass fiber geogrid has very high tensile strength, and can withstand greater external loads during soil reinforcement, reducing soil deformation and settlement.

- Aging resistance: Glass fiber has good aging resistance, and maintains high strength and stability after long-term use, which is particularly suitable for infrastructure projects with long-term use.

- High modulus performance: High modulus enables glass fiber geogrid to quickly transfer stress during application, preventing permanent deformation of the material, thereby effectively enhancing the bearing capacity of the soil.

- Chemical corrosion resistance: Glass fiber has good chemical stability and is very resistant to acid and alkali environments and certain chemicals, which allows it to be used for a long time in chemically corrosive soil environments.

Construction process of fiberglass geogrid

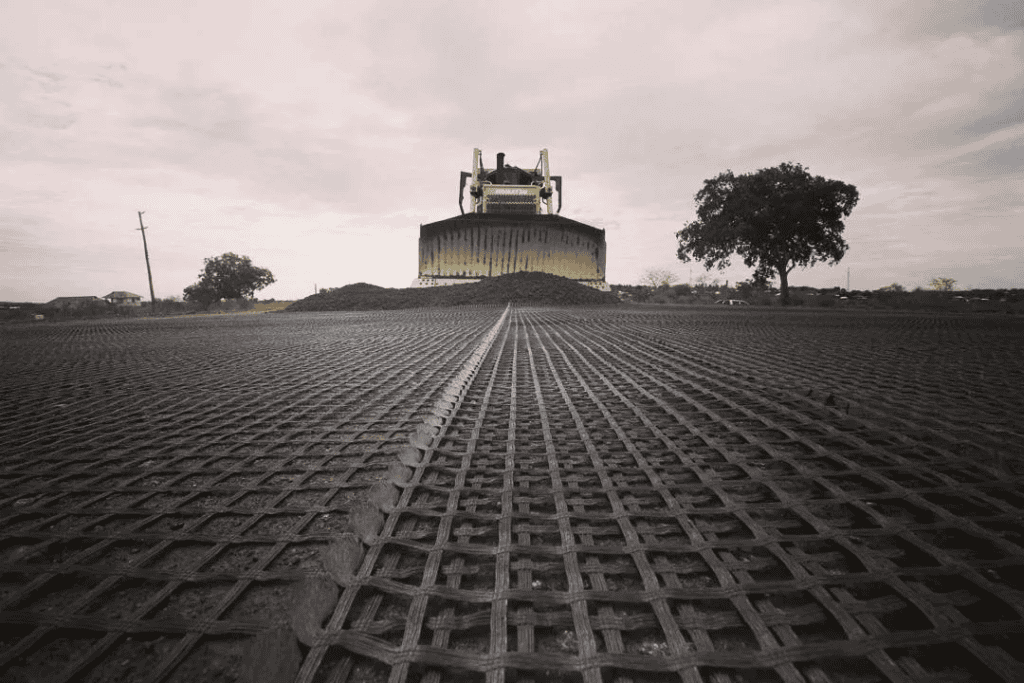

The construction process of fiberglass geogrid is relatively simple and usually includes the following steps:

- Foundation treatment: Before reinforcement construction, the foundation soil layer needs to be cleaned to ensure that the soil is flat and free of debris.

- Laying fiberglass geogrid: The fiberglass geogrid is evenly laid on the treated soil layer to ensure that there is no excessive overlap between the grids and that the grid surface is in good contact with the soil.

- Soil backfill: After laying the fiberglass geogrid, soil backfill can be carried out, and the backfilled soil layer should be gradually compacted to ensure that the geogrid can better play a reinforcing role.

- Rolling and inspection: Roll the backfill soil to ensure that the soil layer is dense, and check whether the laying of the grid meets the design requirements.

Summary

Glass fiber geogrid has become an ideal material for soil reinforcement and road reinforcement due to its high strength, corrosion resistance and simple construction. It effectively improves soil stability and structural safety, and also reduces construction and maintenance costs. The performance advantages of glass fiber geogrid are becoming an important part of civil engineering and infrastructure construction. Its wide application will provide more efficient and safer solutions for future engineering construction. If you have any questions or need to know more about the application of glass fiber geogrid, please feel free to contact us. We will provide professional product recommendations and technical support according to your project needs.