Introduction to HDPE Geocells

In recent years, HDPE geocell have emerged as one of the most versatile and cost-effective solutions in civil engineering, construction, and environmental protection. But what exactly is it, and why is it gaining increasing popularity in infrastructure projects worldwide?

This comprehensive guide will explore everything you need to know about HDPE geocells: what they are, their benefits, key applications, how they compare to traditional methods, and future trends. Whether you’re an engineer, contractor, or someone looking to learn more about this innovative material, this article will provide valuable insights into the world of HDPE geocell technology.

What Are HDPE Geocells?

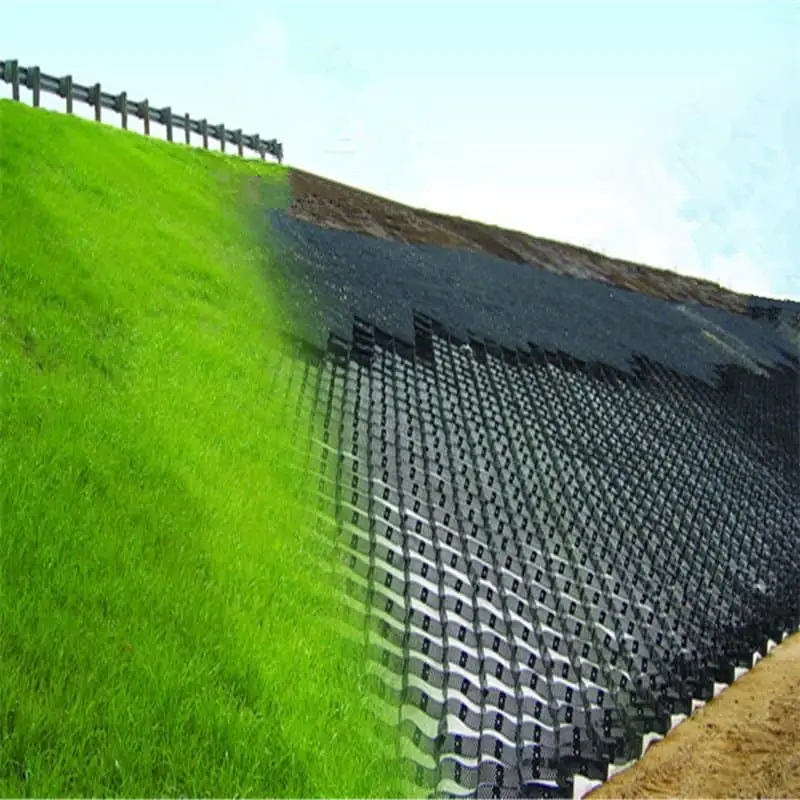

HDPE Geocells, also known as 3D cellular confinement systems, are three-dimensional honeycomb-like structures made from high-density polyethylene (HDPE). These structures are designed to hold and confine soil, gravel, sand, and other fill materials, providing reinforcement and stabilization in a wide range of applications.

The material used in the creation of HDPE geocells is resistant to chemical corrosion, UV degradation, and mechanical stress, making it durable and long-lasting.

Structure of HDPE Geocells

3D cellular confinement systems are typically manufactured in large, interconnected panels or sheets. When deployed, the geocells expand to form a grid-like structure that can hold materials in place, creating a stable and firm foundation for a variety of construction and landscaping projects.

Benefits of HDPE Geocells

The primary advantage of using it is their ability to provide structural support and stabilization in environments where traditional solutions like concrete or asphalt might be expensive, impractical, or environmentally unsustainable. Some key benefits include:

1. Enhanced Load-Bearing Capacity

They are ideal for projects where the load-bearing capacity of the soil is a concern. By confining and stabilizing the material inside the cells, they prevent soil erosion and improve the strength of weak or unstable soils.

2. Soil Erosion Control

One of the most important uses of it is for soil erosion control. By holding soil and gravel together, the geocells prevent the natural erosion caused by wind and water, especially in slopes and embankments.

3. Environmentally Friendly

Because these geocells are made from recyclable, non-toxic plastic materials, they are an environmentally friendly option compared to traditional construction materials. Their ability to reduce the need for concrete or asphalt makes them a sustainable solution for many infrastructure projects.

4. Cost-Effective

They are significantly more affordable than traditional building methods. Their ease of installation and lightweight nature reduce labor and transportation costs. Additionally, their ability to reinforce weak soil means that costly soil treatments or over-excavation are often unnecessary.

5. Flexibility and Versatility

3D cellular confinement systems can be adapted to various construction needs. Whether you’re working on roads, pavements, retaining walls, or landscaping, geocells offer solutions for a wide array of projects.

Applications of HDPE Geocells

HDPE geocells are used across many industries, especially in civil engineering, construction, and environmental management. Here are some key applications:

1. Road and Pavement Construction

HDPE geocells are commonly used in the construction of paved roads, highways, and paths, especially in areas with poor soil conditions. By providing additional stabilization to the subgrade, they ensure that the road surface remains intact for longer periods, reducing maintenance costs and increasing longevity.

2. Slope Stabilization

When used in slope stabilization, HDPE geocells are highly effective in preventing landslides and soil erosion. They are deployed along hillsides and slopes to hold the soil in place, allowing vegetation to grow in the confined cells. This natural vegetation then reinforces the soil, preventing future erosion.

3. Retaining Walls and Embankments

In retaining wall and embankment applications, geocells provide vertical stability and minimize the risk of shifting and collapse. By confining fill material within the geocell’s cells, the structure becomes stronger and more durable.

4. Parking Lots and Load Support

HDPE geocells can be used for permeable parking lots and load-bearing areas, such as military camps, temporary construction sites, and industrial zones. They provide a stable surface while allowing water to permeate the ground, reducing stormwater runoff.

5. Landscaping and Green Infrastructure

In landscaping, HDPE geocells help with green infrastructure projects, such as stormwater management systems and low-impact development (LID) solutions. They help create permeable surfaces for urban parks, green roofs, and drainage systems.

How Do HDPE Geocells Compare to Traditional Methods?

HDPE geocells offer several advantages over traditional construction methods, including concrete, asphalt, and traditional soil stabilization techniques:

1. Compared to Concrete and Asphalt

While concrete and asphalt provide stability, they do not allow for drainage or flexibility. HDPE geocells, on the other hand, allow water to flow through while still providing stability and strength, making them ideal for erosion-prone or environmentally sensitive areas.

2. Compared to Soil Reinforcement Methods

Traditional soil reinforcement techniques, such as the use of geogrids, may offer some similar benefits but tend to be less flexible and more expensive than HDPE geocells. Geocells are lighter and easier to install, leading to cost savings and faster project timelines.

Installation of HDPE Geocells

The installation of HDPE geocells is relatively simple and cost-effective. Here’s a basic overview of the process:

1. Site Preparation

The installation area should be cleared of any debris, and the ground should be leveled to create a uniform surface.

2. Geocell Deployment

The geocells are laid out in the desired pattern and connected using clips or welding. The panels are expanded and anchored in place.

3. Filling the Cells

Once the geocells are in position, the cells are filled with soil, gravel, or other fill materials. This helps to create a stable and strong foundation.

4. Compaction and Final Touches

Once the cells are filled, the material inside the cells is compacted to ensure stability and strength. Additional layers of geocells can be added for extra reinforcement if needed.

Future Trends in HDPE Geocell Technology

As the demand for sustainable, cost-effective construction methods continues to grow, HDPE geocell technology is expected to evolve. Future developments may include:

1. Improved Materials

Research into alternative materials that are even more durable, lightweight, and eco-friendly could enhance the performance of HDPE geocells.

2. Smart Geocells

With the rise of the Internet of Things (IoT) and smart sensors, future HDPE geocells may integrate sensors to monitor load, soil stability, and temperature, providing real-time data for ongoing projects.

3. Green and Sustainable Applications

As the focus on sustainable infrastructure increases, HDPE geocells will continue to play a critical role in green infrastructure projects that prioritize environmental preservation and cost efficiency.

Conclusion

HDPE geocells represent a modern solution for many of the challenges faced by engineers, construction professionals, and environmentalists. Their ability to provide cost-effective, durable, and sustainable stabilization and erosion control makes them an ideal choice for a wide range of projects, from roads to slopes to parking lots.

With their growing adoption across industries and their potential for future advancements, HDPE geocells are set to be a key component in the future of civil engineering and construction.