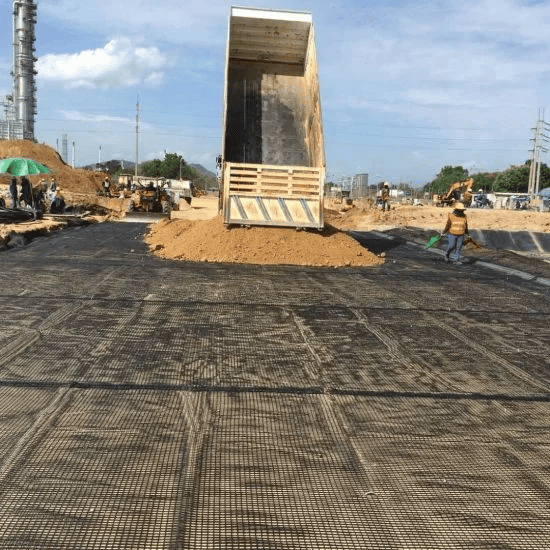

Uniaxial Geogrid Manufacturer produce geosynthetics based on polymer synthetic materials and manufactured by stretching. They are usually used in soil reinforcement, road and infrastructure construction, mine tailings pond reinforcement and other fields. It consists of a series of evenly distributed longitudinal high-strength polymer filaments or belts, with a mesh structure, which has a significant reinforcement effect and is particularly suitable for engineering occasions that need to withstand unidirectional tension.

Unidirectional geogrids are usually made of polymer materials such as polypropylene (PP) and polyethylene (PE), which have high tensile strength, good aging resistance, UV resistance, chemical corrosion resistance and resistance to temperature changes. Through the stretching process, the longitudinal arrangement of the filaments or belts of the geogrid gives it extremely strong tensile strength in one direction, which can effectively enhance the stability of the soil, prevent settlement, displacement and other problems, and extend the service life of the project.

Uniaxial Geogrid features:

- High tensile strength: Unidirectional geogrids have significantly improved the longitudinal tensile strength of the material through the stretching process. This strength enables the grid to play a reinforcing role in the soil, resisting foundation settlement, deformation and displacement.

- Enhanced soil structure: Unidirectional geogrids can play the role of a mesh structure in the soil. By locking soil particles in the mesh of the grid, the slippage of soil particles is reduced, the shear resistance of the soil is improved, and the stability and bearing capacity of the soil are enhanced.

- Aging resistance and weather resistance: Geogrids made of polymer materials (such as polypropylene PP, polyethylene PE) usually have excellent UV resistance, acid and alkali resistance, corrosion resistance and other characteristics, and can work stably for a long time in harsh environments.

- Permeability and drainage: Unidirectional geogrids have a certain porosity, which makes them have good drainage performance. It can effectively remove moisture, avoid excessive water accumulation in the soil, and reduce the risk of soil loosening and sliding.

Advantages of Uniaxial Geogrid :

- Improve bearing capacity: By enhancing the tensile strength of the soil, the bearing capacity of the foundation is significantly improved.

- Prevent settlement and deformation: Effectively prevent settlement, displacement and deformation in areas such as roadbeds and slopes, and ensure the stability of the engineering structure.

- Reduce construction costs: The construction of unidirectional geogrids is simple, reducing construction time and costs.

- Strong durability: Anti-ultraviolet, anti-aging, and anti-corrosion, it can work stably for a long time in harsh environments.

- Good drainage: The pore structure of the geogrid can promote the discharge of water and reduce the impact of accumulated water on the soil structure.

Why choose a leading Uniaxial Geogrid Manufacturer?

High-quality raw materials and production processes

Leading Uniaxial Geogrid Manufacturer usually use high-quality raw materials (such as high-molecular materials such as polypropylene (PP) and polyethylene (PE)) and advanced production processes. Uniaxial Geogrid Manufacturer usually use the latest extrusion molding and stretching processes to ensure that each fiber or belt is strictly stretched, thereby greatly improving the longitudinal tensile strength and durability of the geogrid.

- Customized product design and flexible solutions

Leading Uniaxial Geogrid Manufacturer are usually able to provide customized designs and solutions based on the specific needs of customers. This means that in specific projects, manufacturers can customize geogrids by optimizing material formulations and production processes to ensure that special needs are met according to different projects that require additional tensile strength or corrosion resistance. Customization services are not limited to product specifications, but also include product size, shape, thickness, strength and other aspects, which can perfectly meet the engineering needs of customers. - Efficient technical support and continuous innovation; Uniaxial Geogrid Manufacturer usually have strong technical R&D capabilities and can continuously innovate products and update technologies according to market changes and customer needs. Through continuous technical research and innovation, manufacturers can provide more efficient and energy-saving products and improve the application performance of geogrids in different fields.

Perfect quality control system and after-sales service

- Uniaxial Geogrid Manufacturer Quality control is one of the core competitiveness of leading manufacturers. Top manufacturers usually have a complete set of strict quality control systems, from raw material procurement to production, testing, and delivery. Through quality control, manufacturers ensure the stability of performance and specifications of each batch of products in accordance with national and industry standards.

- Uniaxial Geogrid Manufacturer Strong production capacity and timely delivery; Uniaxial Geogrid Manufacturer usually have strong production capacity and flexible production scheduling capabilities to meet the needs of large-scale engineering projects. Whether it is a long-term cooperative customer or an emergency order, the manufacturer can deliver the product on time and in quantity to ensure that the project is advanced on time. Many leading manufacturers also have a global production and supply chain network, which can provide cross-regional distribution services to ensure that global customers can quickly obtain the required products. Through efficient production and logistics management, leading manufacturers can greatly shorten the delivery cycle and reduce the risk of supply chain interruptions.

- Uniaxial Geogrid Manufacturer Delivery guarantee:

Large-scale production capacity: adapt to the needs of projects of different sizes and provide sufficient supply.

Timely delivery: ensure that orders are delivered on time to avoid affecting the construction progress.

Cross-regional supply: Global supply chain ensures that international customers can receive products in a timely manner.